[最も共有された! √] homemade plywood concrete wall forms 474490-How to build plywood concrete wall forms

The Seawolf™ System utilizes Symons SteelPly™ modular concrete forms for the exposed concrete face and plywood on the inaccessible side This unique approach to onesided wall forming eliminates the need for "weldon" ties, concrete/rock/wood anchors, or "Aframe" supports, which results in dramatic labor and equipment savingsA Forming curved surfaces can be accomplished by using plywood, which can be bent to the desired radius However, the plywood must be thick enough to support the load, or pressure, of wet concrete yet thin enough to bend properlyDec 14, 18 · Construction professionals routinely use plywood panels as shaping forms when pouring concrete for new home foundations If the wood forms were treated properly with a form release agent, you can

Pin On Concrete

How to build plywood concrete wall forms

How to build plywood concrete wall forms-Find the perfect plywood concrete wall form to make quality solid plastic products at Alibabacom Check out a vast periphery of plywood concrete wall form thatEMI Construction Products is your source for construction supplies, including concrete forms, concrete accessories, plywood forms, wall ties, aluminum forming supplies and a variety of other construction materials CAREERS CONCRETE FORMING

4 2 Formwork For Concrete Wall

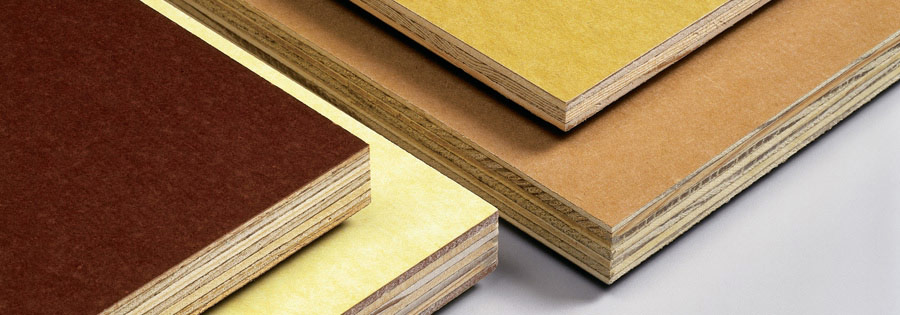

However, plywood used for this purposeshould be made with waterproof glue and markedfor use in concrete forms Plywood is warpresistantand can be used more often than other lumber An advantage of using plywood for forms is thegreat number of sizes available It is made inthicknessesMar 28, 07 · I need to form about 100 linear feet of pouredinplace concrete wall (retaining wall with a 3' freestanding wall on top) Heights vary from 7' to 3', avg is about 5' (500 sq ft of wall & forms) I have another use for the plywood and lumber to build the forms, so I'd prefer to go with shopbuilt forms rather than rentTips For Purchasing Concrete Wall Forms for Modular Prefabricated Buildings Concrete forms are pieces of specialty hardware designed to assist you with the drying and formation of walls The pieces of these forms can be arranged and assembled in a multitude of different ways, allowing you to create various different shapes of walls

The forms The concrete and reinforcing together weigh approximately 24 tonnes/m3 Lateral forces are generated in walls creating horizontal bursting pressures, which are increased by Figure 1 Foundation wall formwork – low walls Figure 2 Foundation wall formwork – walls up to 2 m Note 1 Formwork may be either plywood or timberOCM, Inc #STLEC6HH 6" Wall x 81/4" End Hex Head Plastic Cone Snap Ties can be used with the #3 forming system with 3/4" plywood This snap tie forming method is used for retaining and standard walls, batter walls, bridges, concrete signs, footings, etc They are held in place by a Snaptie WedgeAluminum Concrete Wall Forms New Steel Ply Wall Forms Renovated Steel Ply Wall Forms Decorative Concrete Products Renovation Replacement Plywood & Rivets Regional Concrete Wall Form Rental Job Site Delivery Forming Accessories & Hardware VISIT US Our shipping address is W6261 US Hwy 8 Tomahawk, WI

Jun 28, 11 · The forms are plywood and I want them to come off easily after the concrete is poured People around here usually use diesel However, I'd also like to "fill in" some of the roughness of the plywood, so the finish on the wall is smoother1 1/8" structural 1 grade forming plywood, made of 100% Douglas Fir with 11 plys for added strength and durability DURAFORM was the first to offer chamfered edges and an improved edge seal DURAFORM Concrete Forms are efficient and accurate, saving both time and money!Panels manufactured for multiple reuse as concrete forms Virtually any "Exterior" rated APA panel can be used for concrete formwork because all such panels are manufactured with moisture resistant adhesive For concrete forming, the plywood industry produces a special product called Plyform®, which is recommended for most general forming uses

4 Different Concrete Forms And Their Uses By Forming America

Tips For Building With Board Form Concrete Jlc Online

Plywood is economical to use for wall and floorforms;HForms is a firstofitskind complete, warranted system for creating beautiful landscape walls The system uses insulated concrete form technology to eliminate the use concrete masonry unit (CMU) concrete blocks, and includes all the necessary forms, foundation materials, reinforcing mesh, stucco and accessories needed to complete a projectApr 03, · Beside this, what type of wood is used for concrete forms?

How To Form Board Form Concrete Meadow House

Forming Foundation Walls Youtube

About product and suppliers 1,919 concrete form plywood ties products are offered for sale by suppliers on Alibabacom A wide variety of concrete form plywood ties options are available to you, There are 333 suppliers who sells concrete form plywood ties onTo construct the forms Build the form in sections, using 2 x 4's laid on edge to construct frames that measure the height of the wall and not more than 8' in length Nail 2 x 4 studs into each frame, spacing them on 16" centersApr 03, 11 · Can I reuse the foundation forms (2x8) and, if I build a basement, plywood concrete wall forms?

How To Use Symons Forms Forming America

Q Tbn And9gctdyyuo2ltf2yrbpgkcqwndt Xpnx8 Vuoh0ojmlwhgl Lzcz L Usqp Cau

May 16, · Plywood is an ideal material for concrete forming It produces smooth surfaces and can be used repeatedly – some overlaid panels up to 0 times or more The thinner panels can be bent easily for curved forms and liners Beside this, what type of wood is used for concrete forms?Concrete Foundation Forms 2 x 4's and 3/4″ forming plywood works best The form will be lightweight and strong If they will be reused, then use treated lumberConcrete forming panels are usually plywood with an overlay that protects the wood from the concrete You will likely experience pillowing and release problems The pressure on the lower rods will be high and may damage the stud and washer I don't think it'll collapse but it may shift

Foundation Mono Pours Build Blog

Tips To Build A Concrete Walkway Diy Family Handyman

Giving Form to Concrete Ideas!Plywood is the best material for building concrete forms because it retains its shape and integrity following prolonged exposure to wet concrete Cut OSB panels tend to swell on exposure to water Plyform panels are the best choice since they're specially engineered for concrete formingForming Brock White has a wide range of concrete forming products including column forms and bases, wedges and stakes, inserts and ties from the best manufacturers in the business, including Dayton Superior, Ellis and EMI

Board Form Concrete How To Know What S Good

4 2 Formwork For Concrete Wall

SPECIFYING CONCRETE FORM PANELS General Virtually any Exterior type APA panel can be used for concrete formwork because all such panels are manufactured with waterproof glue For concrete forming the plywood industry produces a special product called Plyform,® which is recommended for most general forming uses The term is proprietary andNov 09, 17 · Snap tie concrete forms are a simple and easy system for foundation wallsThank you for all your support,https//wwwpaypalme/mountainhomestead #essentialmoEMI Construction Products is your source for construction supplies, including concrete forms, concrete accessories, plywood forms, wall ties, aluminum forming supplies and a variety of other construction materials CAREERS CONCRETE FORMING, ACCESSORIES & PRECAST STEEL

Concrete Forms Types And Selection Of Concrete Forms The Constructor

Concrete Wall Reveal Blue Heron Ecohaus

Sep 01, 1995 · The curve of the wall has a radius of 4 feet Can we produce this curve using jobbuilt forms?Click to add item Roseburg BBOES 3/4 x 4 x 8 Concrete Forming Plywood to your list Sku # Online Price More Information $ You Save $13 with MailIn RebateI thought maybe the 2x8's as rafters, ceiling joists, or for whatever comes up, and 3/4" plywood wall forms as sheathing or something

Stepped Concrete Foundation On A Slope Scott Herndon Homes General Contractor Blog 11 10 18 Sandpoint Idaho

Gates Concrete Forming Systems

BBOES BBOES is concrete forming plywood made from Fir trees It is a popular and widely used solution for concrete forming It is a stable, high strength 7 ply Fir veneer The outside layers are B grade, and are sanded providing for a smooth finish on the concreteSnap tie concrete forms are a simple and effective way for anyone to be able to pour concrete effectively and inexpensive If you are looking to save money bBBOES BBOES is concrete forming plywood made from Fir trees It

How To Form Board Form Concrete Meadow House

Www Constructionknowledge Net Public Domain Documents Div 6 Woods Plastics Partial carpentry pdfs Forms Concrete army Fm5 426 Pdf

Tured for concrete form use and, if so, are designated "Concrete Form" on their trademark During plywood production, these overlays are bonded to the plywood under high heat and pressure in a press The function of the overlay is to add stability, repel foreign substances from the surface and provide a smoother and more durable formingOct 08, 01 · Re plywood for concrete forms My experience in the forming has been using 3/4 inch plywood Use CDX for speciality forms or 1 or 2 pours (because it is cheap) Special plywood oil soaked (mdo) work for about 6 to 7 pours and corners and edges start coming apart but can get 10 pours plus out of themFeb 27, · Concrete does adhere to wood, though the connection is often not ideal Many builders use wood panels as forms that concrete is poured into to create a foundation or floor After the concrete is cured and dry, the wood is removed If you don't want concrete to stick to wood, you would need to use a release agent to make removal easier

One Man Formwork Concrete Construction Magazine

4 2 Formwork For Concrete Wall

Oct 17, 16 · The 232 plywood panels were precut, numbered, and organized in order of assembly and finally installed on the forms in the order and orientation specified on the concrete shop drawings All column, wall, and beam forms were doublesheeted with 3/4inch plywood substrates and 3/4inch plywood with a film fasciaFull and nominal size Aluminum Form Ties compatible with WallTies, Western Forms, and Precise style concrete forming equipment Resi Ties (DISCONTINUED) Resi Ties for 11/8″ Plywood or "Resi Ply" forming systems availableDec 13, 17 · Nearly all types of plywood panels can be used in concreteforming, from common roof and wall sheathing to sanded panels APA Plyform panels, however, are specifically designed to withstand the wearandtear of repeated concrete pours, as well as to provide a smoother and more consistent finish to the concrete's surface

Footings And Foundations With Snap Tie Forms For Building Your Cabin Or Home Youtube

Builderup Projects Insulated Concrete Form Construction

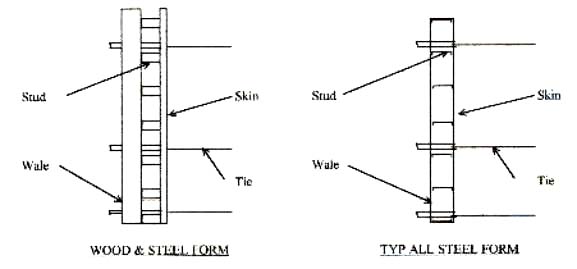

Apr 02, 16 · As shown on the APA Concrete Forming guide linked above, it takes A LOT of 2x wood external bracing when forming walls with plywood From the guide above, assuming 1/2" plywood with the face grain across the supports, 70F concrete, and a slow 2ft/hr pour rate, you will need a vertical 2x4 support every 12" with a double 2x4 horizontal support (wale)May 14, 08 · There were a couple bridges built nearby and the formwork for the abutments and concrete retaining walls were built with 3/4" OSB which is a lot cheaper than plywood Once the forms were stripped, the concrete was parged to cover the OSB "design impressions" and itConcrete Forming Plywood SKU Make a selection $6484 $ **DISCLAIMER** ALL Wood/Lumber pricing on our site for these items can not be held and whatever the posted price is at the time of purchase is correct **Product will be shipped out from Edmonton,

Home Building In The Virgin Islands Concrete Vs Plywood

Formwork Designing Buildings Wiki

Jan 18, Explore Darrell Tipton's board "concrete molds", followed by 372 people on See more ideas about concrete, concrete diy, concrete projectsA selfcentering loop tie and TieLock Bracket, with 3/4" plywood as the form face and 2×4 lumber as the waler, creates an economical concrete forming system The selfcentering tie sets the wall dimension, sits flush up against the plywood face, and breaks back cleanly within the plastic coneWill outperform the competition pour for pour

Overlaid Hdo Mdo Apa The Engineered Wood Association

4 Methods Of Building Concrete Formwork Youtube

Aug 21, 16 · Concrete wall forms are typically made of plywood, aluminum, or steel Many consider aluminum and steel wall forming systems to be more productive, efficient, and even economical than wood forming Plywood forms are typically used where unique wall shapes, sizes, and embedment characteristics are presentConcrete form release agent, or form release for short, is a product that's applied to concrete molds, frames and forms to prevent the concrete from sticking as it cures Don't forget to apply form release oil to your concrete forms before pouring, even if you cannot find it on the market

Job Built Concrete Forms Vs Form Systems Be The Pro

How To Form Concrete Walls With Pictures Wikihow

Build A Concrete Root Cellar

Material Recommendation For Curved Form Concrete

Formwork Panel Steel With Plywood For Column Concrete Walls Buy Construction Formwork For Sale Formwork Hammer For Sale Plastic Formwork For Sale Product On Alibaba Com

Concrete Formwork Basics Branz Build

How To Form Concrete Walls With Pictures Wikihow

Pin On B K Szalunki

Concrete Walls With A Curve Tips For Forming And Pouring Youtube

Tips For Building With Board Form Concrete Boothe Concrete

How To Form Concrete Walls With Pictures Wikihow

Placing A Concrete Foundation In One Pour Pro Remodeler

Concrete Form Seasoning And Material Selection

Birch Plywood For Concrete Formwork

Www Constructionknowledge Net Public Domain Documents Div 6 Woods Plastics Partial carpentry pdfs Forms Concrete army Fm5 426 Pdf

Concrete Construction With Aluminum Forming Systems

How To Form Concrete Walls With Pictures Wikihow

Birch Plywood For Concrete Formwork

Intro To Jahn Concrete Formwork Systems Part 2 Youtube

Gates Concrete Forming Systems

How To Keep Concrete From Sticking To Wood

Types Of Form Ties Used In Formwork The Constructor

Forming Concrete Foundation Walls

Concrete Formwork Basics Branz Build

Www Quikrete Com Pdfs Projects Concretewalls Pdf

Are My Concrete Forms Holding The Concrete

Forming Concrete Foundation Walls

Viewing A Thread Pics Concrete Forms Blew Out I Had A Fun Day

Forming Concrete Foundation Walls

How To Form Concrete Walls With Pictures Wikihow

Concrete Forms Steel Vs Wood Forming America

Foundation Mono Pours Build Blog

Concrete Form Panels Apa The Engineered Wood Association

Designing Forms For Tall Concrete Walls Fine Homebuilding

Concrete Form Types Networx

1

Board Form Concrete How To Know What S Good

Pin On Wooden Wall

Tips For Building With Board Form Concrete Jlc Online

Pin On Concrete

Concrete Forms Forming Concrete With Wood Forms Youtube

How To Pour A Concrete Retaining Wall Doityourself Com

What Are Concrete Forms What Are They Used For

Concrete Formwork Alternatives For Construction Pros

Blindside Walls Concrete Wall Form

Specifying The Right Plywood For Concrete Formwork Construction Specifier

3

Board Formed Concrete Life Of An Architect

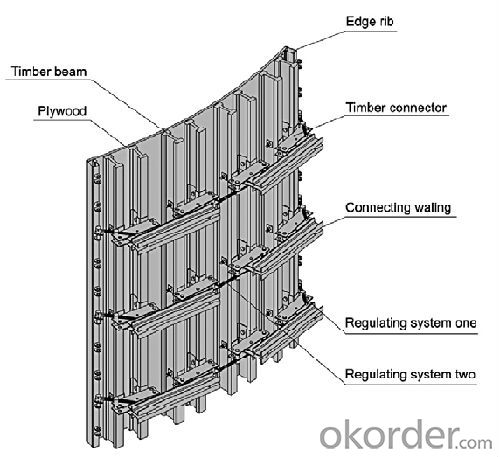

Timber Beam Formwork For Curve Concrete Wall Formwork Real Time Quotes Last Sale Prices Okorder Com

Pin On Architecture Details And Materials

Pin On Albanileria Y Manposteria

Concrete Wall Forms For Sale Ebay

How To Form Concrete Walls With Pictures Wikihow

Rammed Earth Formwork

Birch Plywood For Concrete Formwork

Is It Necessary To Have Plywood On Cabinets Under Concrete Countertop

Greenhouse Wall Forms Wired Sugar Mountain Farm

3

Concrete Formwork Alternatives For Construction Pros

Concrete Forming Systems Options Considerations Design And Cost

How To Form Concrete Walls With Pictures Wikihow

4 2 Formwork For Concrete Wall

Concrete Wall Forms For Sale Ebay

Curved Concrete Wall Forms Plywood Sheet Buy Concrete Forms Concrete Wall Forms Plywood Sheet Product On Alibaba Com

How To Form Concrete Walls With Pictures Wikihow

Using Prefabricated Wood Forms Concrete Construction Magazine

Poured Concrete Wall Adventures In Remodeling

Form Construction Engineer Educators Com

Forming Concrete Walls Fine Homebuilding

Forming And Placing Concrete For The Garage Fine Homebuilding

Form Construction Engineer Educators Com

Reusable Plywood Concrete Wall Forms Metal Forms For Concrete Walls

Basement Formwork

Forming Concrete Foundation Walls

Tips For Building With Board Form Concrete Jlc Online

Cost Comparison Plywood Vs Icf

Concrete Plywood Forming Strip Tie Snap Tie And Wedges Buy Formwork Strip Tie Construction Formwork Concrete Formwork Product On Alibaba Com

Shuttering Plywood And Formwork Panels

How To Build A Pool Wall Aqua Magazine

How To Form Concrete Walls With Pictures Wikihow

コメント

コメントを投稿